jeffrey hammer mill working principle - mtbhotel.de

Hammer mill by Saraswathi.B - Pharmainfo . Principle and working of hammer mill. Working of the hammer mill. Principle: It works on the principle of impact that is material is more or less stationary and is hit... Get Quote

Hammer Mill Operating Principle

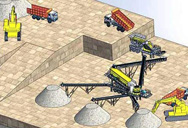

The Jeffrey Miracle Hammer Crusher is designed for the reduction of large pieces and large capacities of limestone, shale, slag, and cement rock. The larger sizes are built to take steam shovel size limestone, crushing it into pieces 1″, 2″, 3″, or 4″ and under, in one operation, the one unit doing the work ordinarily done by two or more of other types of crushers. This enables large reduction of limestone and other …

jeffrey hammer mill working principle - …

Hammer Mill Working Principle Pdf A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sinteringt works on the principle of impact and attrition size reduction is done by impact as the balls drop from near the top of the shell ball...

How Does a Hammer Mill Work?

Work? Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill’s chamber through the . feed chute, typically by gravity. • The material is struck by . ganged hammers (generally rectangular pieces of hardened steel) which are attached to a . shaft. that rotates at high speed inside the mill’s

principles of operation of a hammer mill

Gold Hammer Mill Working Principle For Stone Crusher Plant , Find Complete . will crush, shatter, or pulverize upon impact using a simple three step operation: . table,centrifugal . Impact Crusher Principle Of Operation | Crusher Mills . 2018-10-22 · This design produces three major principles which all interact when breaking materials using sizer technology. working of impact crusher ...

hammer mill works on the principle of

jeffrey hammer mill working principle. Hammer mills: hammermills . ... - work with any friable material and fibre - ease of use - lower initial investment when compared with a roller mill ... The number of hammers used for a hammer mill of 1,800 rpm, should be 1 for every 2.5 to 3.5 horsepower, and for 3,600 rpm, one for every 1 to 2 horsepower. ... Sales Online. NEA - Hammer Mill - Neuman ...

Hammermill - Wikipedia

The basic principle is straightforward. A hammer mill is essentially a steel drum containing a vertical or horizontal rotating shaft or drum on which hammers are mounted. The hammers are free to swing on the ends of the cross, or fixed to the central rotor. The rotor is spun at a high speed inside the drum while material is fed into a feed hopper. The material is impacted by the hammer bars and is thereby …

working principle of the hammer mill

jeffrey hammer mill working principle. liming Vertical Hammer Mill 75 Kw. Working principle of hammer mills youtube in the past 20 years we devote to producing hammer mill dfzc working principle liming vertical hammer mill 75 kw liming hammer mill read more used milling for sale openshaw plant machinery. Online Chat Hammer Mill Feeder Dfzc1265 Dfzc600 liming . Get Price Or Chat …

Hammermill Maintenance - CPM

as 38” diameter mills with 1800 RPM motors. As hammer manufacturers improve the quality of the hardface edge treatments available, hammers last longer and exaggerate any problems with hammers rocking on the pins. In some cases it may be necessary to change the hammer pattern by adding more hammers to prevent excessive hammer pin hammer hole wear. Always consult with the hammermill ...

Hammer Mill Crusher Working Principle

Hammer crusherhammer mill. 2018-4-10the working principle of hammer crusher materials go into the hammer crusher and crushed by the high-speed rotating hammer driven by the hammer the crushed materials then throw to the crushing plate and the large size materials are crushed by... Details

Working principle of hammer mill crusher

Working Principle 1 Hammer mill mainly consists of frame rotor support iron and grate bars 2 Large materials entering the crusher through the feed inlet are stricken impacted cut and ground by the highspeed hammers to small size . Hammer CrusherHammer Mill Stone CrusherHammer . Hammer Crusher Operating Principle The main working part of hammer crusher is rotors with hammer The …

The Working Principle of Hammer Mills Stepby …

The Working Principle of Hammer Mills Stepbystep Guide A hammer mill is an essential machine in the pharmaceutical and stone processing industries You can use it to crush pulverize shred grind and reduce material to suitable sizes Even though there are many types of hammer mills the working principle is still the same . Email: [email protected] Get a Quote Send Message. Products Show …

hammer mill working principle crusher spares …

Hammer Mill Operating Principle. Hammer Crusher. The Jeffrey Miracle Hammer Crusher is designed for the reduction of large pieces and large capacities of limestone, shale, slag, and cement rock. The larger sizes are built to take steam shovel size limestone, crushing it into pieces 1″, 2″, 3″, or 4″ and under, in one operation, the one ...

Water Jacketed Hammer Mill Principle And Working

Jeffrey Hammer Mill Working Principle - Stone(Ore) Crusher ... Home Screening machine water jacketed hammer mill principle and working. About Us. SHANGHAI SMMI MACHINERY CO., Operating principle of hammer mill Hammer Mill Working ... Principle of Vertical Grinding Mills - CGM Grinding Plant. Principle of Vertical Grinding Mills. ... The fluid product to be dispersed is pumped …