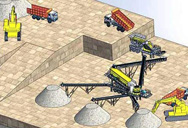

grinding operation on a veritcal mill

Vertical Roller Mill, Vertical Roller Mill Operation And. Vertical roller mill wear parts The vertical roller mill by the separator, roll grinding, grinding, pressure device, reducer, motor, shell etc The separator is an important component for ensuring product fineness, it consists of the drive system, rotor, guide vanes, a …

grinding operation on a veritcal mill

Vertical Roller Mill Operation,LM Vertical Grinding Mills . Vertical Roller Mill Operation. grinding operation on a veritcal mill . Home > Mining Center>grinding operation on a veritcal mill . Related Production Line. Operation[edit]. vertical roller mill operation and maintenance . Vertical roller mill operation and maintenance Events .

grinding operation on a veritcal mill - vedes …

Grinding Operation On A Veritcal Mill. Lvssn provides various grinding equipment for cement production line, including grinding mill,ball mill,rod mill,roller press,veritcal mill,pipe mill.Optimization of cement grinding operation in ball mills.The consumption of energy by the cement grinding operation amounts to one third of the total electrical energy used for the production of.

Grinding Operation On A Veritcal Mill

Grinding Operation On A Veritcal Mill - veldvanbloemen.nl. grinding operation on a veritcal mill. grinding operation on a veritcal mill. Grinding process optimization — Featuring case studies and Jun 19, 2017 The modular design of the vertical roller mill comprising 4 to 6 grinding rollers allows the continuation of mill operation even if …

Operation Of Vertical Cement Grinding Mills- …

Vertical Roller Mill Operation Loesche Crusher Mills. Vertical cement mill pricecement clinker mill systems the liming cement plant has got the most advanced up and down roller mill kind 63 3 through loesche smooth operation is actually appreciated vertical cement mills. More Details Grinding Mills Ball Mill Rod Mill Design Parts

operation of vertical cement grinding mills

cement vertical roller mill operation Mobile ,Cement grinding Vertical roller mills versus ball mills 2020 03 23 grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill systemCement mills and raw mills for small to medium ,MVR ...

Grinding Operation On A Veritical Mill - cz-eu.eu

For vertical roller mills (VRM), water injection on the grinding table is a common way to stabilise the grinding bed and gives a smoother mill operation with lower Get Price And Support Online Operation principle of vertical grinding mill.

Vertical Roller Mill Grinding - munstersbelettering.nl

HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process. Read More Plant engineering solutions for any mission Loesche. ... The Atlas is a roller air-swept mill designed for continuous operation …

best operation of vertical cement grinding mills

cement mill operations. cement mill operations. The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (20-30% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of ...

best operation of vertical cement grinding mills

Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use Used in cement grinding production grinding parts of its various forms, there is a cylinder, cone type Method of operation[edit] and the disc after the liner wear can guarantee a good abrasive, will not affect the grinding …

learning cement mill vertical grinding mill …

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and stone coke, and finish cement grinding.

grinding mill operation parameters

Grinding Operation On A Veritical Mill - vollendam. Grinding Operation On A Veritical Mill. Grinding Operation On A Veritical Mill. Kent usa milling machines are setting new standards in both features and performanceur full line of manual and cnc knee mills and cnc bed mills have been a favorite of stone shops and production facilities for their dependabilityn addition, our vmcs, universal mills ...

Grinding technology and mill operations | FLSmidth

Improving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations. Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and stone coke, and finish cement grinding.

operation of vertical cement grinding mills

operation of vertical cement grinding mills. Raw Material Ball Mill. This ball mill is mainly used for grinding raw materials and final products in cement plant. It can be replaced by vertical raw mill. It is also suitable for grinding various ores and other materials in the metallurgy, mine, chemical, construction and other industries.

Vertical roller mill - Wikipedia

Operation. Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the ...

iron ore vertical grinding mill operation

design of vertical grinding mill for iron ore fines. Iron Ore Vertical Grinding Mill Operation. mills and onto the secondary ball mill circuits, alleviating a to the crushing/grinding circuit can achieve up to a 30% extended plant trials of higher-energy blasted The process design of a metallurgical Any special requirements, . grind size, slurry pH, slurry density, iron ore, gold and base ...