Bilder von jaw crusher rock size

Jaw Crusher Rock Size

Rock Crusher Eastman Rock Crusher. The discharge size is controlled by the setting or the space between those two pieces of steel.The tighter the setting, the smaller the output size and the lower the throughput capacity.As a compression crusher, jaw crushers generally produce the coarsest material because they break the rock by the natural inherent lines of weakness.

Size Of Rock The Jaw Crusher - thermografie …

Differences Between Fixed Jaw Crusher And Impact Rock. The feeding size of fixed jaw crusher ranges from 120750mm Different working principles of the impact rock crusher and fixed jaw crusher During the working process of impact rock crusher rotors are driven by the motor to rotate at a high speed. Read More

Jaw Crusher|Density Of Crushed Rock Related To …

Bulk density of crushed rock jack higgins about 57 limestone gravel the size of 57 stone is 1 inch and under 57 stone is the most common driveway gravel in florida 57 stone is commonly used as a drainage gravel 57 stone is also used in mix concrete mix asphalt and as bases for retaining walls and driveways 57 stone can also be applied in irrigation and on gravel roads 57 stone is an

Jaw Rock Crusher Inch - thomasstroeckens.de

Jaw Rock Crusher Inch. Product capacity : 5-2200t/h. Max Feeding Size : 125-1500mm. Output Size : 10-400mm . Jaw crusher is the vital equipment in crushing industry. The highest compressive strength of the crushing materials is 320Mpa. Learn more 40 years of industry experience providing one-stop solution. COMPANY INFORMATION. Note: If youre interested in the product, please submit your ...

Jaw crushers - liming

Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce rocks to smaller sizes for the next crushing stages. Jaw crushers are a popular alternative to primary gyratory crushers, since they can process large amounts of hard material efficiently. For 45 years, liming C Series jaw crushers have proven their reliability ...

(PDF) SIZE REDUCTION BY CRUSHING METHODS

A crusher is a machine designed to reduce larg e rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more

Primary Crusher Selection & Design

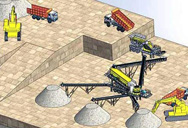

Primary crushers with crush run-of-mine rock from blast product size to what can be carried by the discharge conveyor or fit/math the downstream process. A typical example of primary crushing is reducing top-size from 900 to 200 mm. In Selecting a primary crusher you need to worry about these requirements: That crusher must be capable to reduce the size of even the lastest rocks it is fed.

Crusher - Wikipedia

Primary crushing reduces the large pieces to a size which can be handled by the downstream machinery. Some crushers are mobile and can crush rocks as large as 1.5 meter (60 inches). Primarily used in-pit at the mine face these units are able to move with the large infeed machines (mainly shovels) to increase the tonnage produced.

MBMMLLC.com: Crushing granite with a jaw …

27.11.2014 · Published on Nov 26, 2014 This was a request by one of our customers who cuts granite blocks for monuments and other decorative stone. The 10"x16" jaw crusher was used to crush these 8…

Crushers - an overview | ScienceDirect Topics

Jaw crushers find a wide application for brittle materials. For example, they are used for comminution of porous copper cake. A Fritsch jaw crusher with maximal feed size 95 mm, final fineness (depends on gap setting) 0.3–15 mm, and maximal continuous throughput 250 Kg/h is shown in Fig. 2.8. Sign in to download full-size image

Primary Crusher - an overview | ScienceDirect Topics

The primary crusher is located in the quarry and consists of a McLanahan 48″x72′ Shale King Crusher rated at 1,000 TPH (Tons Per Hour). The driving flywheel has a diameter of 2.5 meters and is motor driven through six v-belts.

Homemade gravel: Industrial rock crushers …

28.12.2016 · These heavy duty industrial rock crushers make light work of turning even the strongest stones into gravel. Todays machines are more impressive than ever, and …

Rock Crusher- Jaw& Cone Rock Crushing Machine

How Does A Rock Crusher Work: The working principle of jaw rock crushers for sale is: when the stone crushing equipment works, motor drives belt and pulley to move, and the eccentric shaft drives the mobile jaw plate. When the mobile jaw plate rises, the angle between elbow plate and mobile jaw …

Jaw Crusher|Rock Crusher Monster Size

Rock Crusher Monster Sizein Bangladesh Vetura Mining. Rock crusher monster size rock crushing rule of thumb mineral processing metallurgy metallurgical content crusher selection crusher design crusher installationcrusher coststhe crushers rock breakersarea of application here is a list of rules of thumb often used in rock crushing and around crushers crusher selection for a hard rock mine