Jaw Crusher For Copper Process - vollendam.nl

Jaw Crusher Mineral Crushing & Aggregate . Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing. it had a wide range of suitable materials, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore and so on. the jaw crusher …

Design Copper Ore Crusher Plant

Copper is generally low in the deeper, larger particle size. so copper mining process plant design must be reasonable, so as to ensure the concentrate grade. at present, the domestic copper mining process plant equipment commonly used include hammer crusher, jaw crusher, roll crusher, cone crusher, and in recent years has developed impact crusher.

Laboratory Jaw Crusher - Metallurgist & Mineral Processing ...

A Laboratory Jaw Crusher engineered for pre-crushing of extremely hard up to brittle materials. The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard …

Dising Jew Crusher Mineral Copper

Jaw crusher,Jaw crushers,Jaw . minerals in the copper . Xinhai Mining Technology provides "Turnkey Solution for Mineral Processing Plant" including design and . Get Price And Support Online; China Primary Jaw Crusher,Mine Minerals Cone Crusher . PE series jaw crusher is . It supplies a variety crusher equipments and also design .

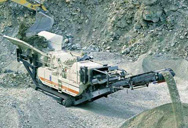

Copper Ore Crushing Production Line, Mobile Crusher ...

The innovative design of mobile copper crusher machine offers owners the highest possible fatigue strength, truly mobility and flexibility, excellent reliability and numerous mounting possibilities.

design of copper ore beneficiation plant

Application Material: copper-molybdenum ore Introduction: According to the natural condition, terrain, and features of copper-molybdenum ore in Mongolia, our Fote specialists design the plant with machines like PE jaw crusher, PEX impact crusher, ball mill, Copper Flotation Beneficiation Plant Design

R Crusher Wear Parts Reference Guide

crusher tools E.G. Jaw liners are subject to numerous pressure and impact stresses. Several other factors affect the wear lifetime of crusher wear parts as listed in below Diagram . Wear occurs in all crushers , however wear costs can be controlled by selecting the correct crusher …

Primary Crusher Selection & Design

A crusher’s wear parts need to last as long as operationally-economically possible. Typical numbers are for liner and mantles to have a useful wear-life of almost 2,000,000 tonne on abrasive taconite and 9,000,000 tonnes on porphyry copper ores. Dependability and long service life are landmarks of good primary crusher design …

Crushing in Mineral Processing

Primary crushers are designed so that the maximum size that can be presented to the crusher is approximately 80% of the gape. Jaw crushers are operated to produce a size reduction ratio between 4 :1 and 9 : 1. Gyratory crushers …

How To Design A Copper Ore Crusher Plant

About 49 of these are mineral separator 13 are crusher and 1 are water treatment. Get Price And Support Online Design Of Copper Processing Plant - spf-production. ... Get Price small copper ore jaw crusher design for copper …