Tower mill - Wikipedia

A tower mill is a type of vertical windmill consisting of a stone or stone tower, on which sits a wooden cap or roof, which can rotate to bring the sails into the wind.. This rotating cap on a firm masonry base gave tower mills great advantages over earlier post mills, as they could stand much higher, bear larger sails, and thus afford greater reach into the wind.

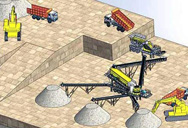

Tower Grinding Mill Simulation - qubical-westland.nl

Ball Mill Design Power Calculation. Stirred mills tower mills for efficient customised application For fine and ultra-fine grinding stirred mill and tower mill technology provides efficient solutions to meet your needs These mills operate at power intensities that give you unrestricted customization options for a wide range of industries and ...

Mill (grinding) - Wikipedia

A VSI mill throws rock or ore particles against a wear plate by slinging them from a spinning center that rotates on a vertical shaft. This type of mill uses the same principle as a VSI crusher.. Tower mill. Tower mills, often called vertical mills, stirred mills or regrind mills, are a more efficient means of grinding material at smaller particle sizes, and can be used after ball mills in a ...

TowerMill - Mischtechnik - Mischer - Intensivmischer

Wet grinding – continuous Vertical agitated media mill for energy efficient fine grinding

TOWER FINE MILLING EXPERIENCE AT MOUNT ISA MINES

The Tower mill is a vertical stirred grinding mill which can be used in both dry and wet grinding applications. It has provided a means of size reduction in an area where conventional tumbling mills become inefficient (Morrell et al, 1993). The major advantage of the Tower mills over the ball mills in

Stirred mills for milling & grinding | FLSmidth

Stirred mills & Tower mills — simple, effective and cost efficient As lower ore grades and complex mineralogy are driving demand for more efficient fine grinding, you can depend on FLSmidth for a full range of fine-grinding mills designed for easy shipment, simple erection and trouble-free maintenance.

Regrinding and fine grinding equipment-tower mill …

26-12-2014 · Offical website:【http://www.bailingmachinery.com/】 Alibaba website:【http://zzbailing.en.alibaba.com/】 Product webpage:【http://www.bailingmachinery.com/produc...

Vertimill® - liming

Vertimill® is an energy efficient grinding machine. They tend to grind more efficiently than for example ball mills with feeds as coarse as 6 mm to products finer than 20 microns. This provides up to a 40% higher energy efficiency. With the Vertimill® simple and robust design, limited liner replacement is …

Stirred Mills – Ultrafine Grinding - ScienceDirect

01-01-2016 · This has less of an effect in tower mills compared with pin stirred mills due to the lifting effect of the screw flights in the tower mill. In the case of pin stirred mills, the grinding media pressure due to gravitational force was considered by Jankovic [9] as (10.3) P m = ( ρ m − ρ SL ) g H , N / m 2 and the media stress intensity at a plane, H , as (10.4) S I g = d m 2 ( ρ m ...

Swiss Tower Mills Minerals AG

Swiss Tower Mills Minerals AG develops fine and ultra-fine grinding mill products, using an innovative technology. A range of services is available from consulting, conceptual and detail engineering to production, site assembly and lifecycle service support.

Tower Mill Grinding of Molybdenite Concentrate

M = solids mill throughput (t/h) Tower Mill Efficiency. A convenient way to compare the Tower mill grinding efficiency with that of other mills is to develop a correlation between net specific energy and product size. This would be desirable not only for comparative purposes, but also for design and scale-up calculations. E = specific energy ...

Publications - SMC Testing

The Application Of Population Balance Models To Very Fine Grinding In Tower Mills Ag And SAG Mill Circuit Selection And Design By Simulation The Decision To Opt For High Pressure Grinding Rolls For The Boddington Expansion An Alternative Energy-Size Relationship To That Proposed By Bond For The Design And Optimisation Of Grinding Circuits

MM18 Tower mill - YouTube

16-03-2014 · MM18 Tower mill Leonard Nimoy. Loading... Unsubscribe from Leonard Nimoy? ... How Vertical Grinding Mills Work (Coal Pulverizer Example) - Duration: 14:39. saVRee 3D 14,320 views.

Vertical Roller Mills - FLSmidth

We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades. The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials. It is increasingly used as a solution for efficient grinding.

Ball Mill Design/Power Calculation - LinkedIn

12-12-2016 · Ball Mill Power Calculation Example. A wet grinding ball mill in closed circuit is to be fed 100 TPH of a material with a work index of 15 and a size distribution of 80% passing ¼ inch (6350 ...

A New Concept in Fine Grinding - Swiss Tower Mills Minerals AG

Metallurgical Plant Design and Operating Strategies (MetPlant 2013) 15 - 17 July 2013, ... The vertical stirred media grinding mill uses a grinding chamber filled with small beads whereby ... in co-operation with Swiss Tower Mills (STM) minerals and Kärtner Machinenfabrik (KMF).

An optimized design of the mill liner and grinding …

Jan 17, 2020 - An optimized design of the mill liner and grinding media system can help increase energy efficiency. The key is to ensure that these components operate as an integrated system rather than as isolated parts. ME Elecmetal provides customers with technical assistance and expertise in both design and manufacture of mill liners and grinding media.

SLURRY FLOW IN A TOWER MILL - CFD

DEM is used to model the grinding media in the tower mill, and SPH is used to model the fluid slurry. The methodology used here for the coupled DEM particulate / SPH slurry model follows that proposed by Cleary et al. (2006a). With this approach we: 1. Perform a 3D DEM simulation to predict the flow of the media in the tower mill.

Visual Encyclopedia of stone Engineering

Tower Mill System Feed enters the grinding chamber through the rotary feeder. The particles fall down a chute into the grinding chamber. In the grinding chamber a double helix screw rotates on a shaft, inducing the particles to grind against each other.