Improving Mill Shoe Bearing Reliability and …

During mill start-up, the slide shoe bearings requires pre-lubrication. This is provided by a high pressure oil pump which delivers oil between the bearing and journal. The oil, injected under pressure, lifts the mill and helps to reduce the friction between the shoe and ring, providing alignment. The minimum oil viscosity for most mills is 44 ...

Ball Mill Trunnion Bearing Lube System

On a 11’-6” x 22’-0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during start-up of the mill. System monitors including pressure switches and flow monitors are provided, along with temperature sensors that monitor ...

Ball Mill Hydrostatic Slide Shoe Bearing | Bearing ...

Ball Mill Hydrostatic Slide Shoe Bearing - Free download as Powerpoint Presentation (.ppt), PDF File ... the high pressure pumps and the oil flow dividers for supplying lubricating oil to the bearing shoes, ... Page 2 bearing shoe bearing shoe in outside position for lift …

Ball mill - Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical

cement Ball mill oil pump for lifting | worldcrushers

Lift & Lube for Ball Mills: Ball Mill … pumps, air to oil cooler etc … φ4.2×14m Cement Mill–China Pengfei Group Co.,Ltd. Tube mill/Ball mill/Cement mill/Coal …

Lift Pump For Ball Mill Coal Pulverizer - ie13.fr

Lift & Lube for Ball Mills: Ball Mill … pumps, air to oil cooler etc … φ4.2×14m Cement Mill–China Pengfei Group Co.,Ltd. Tube mill/Ball mill/Cement mill/Coal … Contact Supplier pulverizer model hp883 943 bowl mills - pochiraju.co.in

ball mill lube system

Ball Mill Trunnion Bearing Lube System The ball mills low pressure oil system pumps oil from the reservoir through a filter assembly to clean the oil before the flow is sent to the trunnion bearings. During start-up, the oil is also pumped to the high pressure pump. Get Price.

Ball Mill Low And High Oil Pressure System Pdf

ball mill low and high oil pressure system pdf. ball mill low and high oil pressure system . ball mill low and high oil pressure system . Get Price And Support Online; Boilers - me.ua.edu. The refractory lining is a high maintenance item. . brought to a burner at elevated pressure and jetted (gas) or sprayed (oil) . Ball Mill Coal Pulverizer.

Ball Mill Maintenance & Installation Procedure

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles ...

Mill Lubrication System - LinkedIn SlideShare

Hydraulic Lubrication System A mechanical system of lubricating engines in which a pump forces oil to flow into their ... Oil Pressure, (psi) 30 32 58 60 60 60 0.15 0.20 0.36 0.58 0.31 0.35 PT554 Dis. End Trunnion Bearing Lift 20. Parts of Ball Mill to be ... Mill Current Oil …

ball mill trunnion hydraulic lift pump and internal …

ball mill lift pump oil . ball mills .get usa ball mills manufacturers.trunnion hydraulic lift pump trunnion. business lines during the about ball mill lift pumps related . Get …

ball mill lubrication system - miss-sushi.fr

Ball Mill Lubrication Systems. Ball Mill Trunnion Bearing Lube System On a 11-6" x 22-0" Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and discharge trunnions during start-up of the mill.

functioning of ball mill lubrication system

Ball mill operation and maintenance-Shanghai liming Mining ... Oct 24, 2012 ... Ball mill operation and maintenance. ... The order start machine is:First start the ball mill oil pump. ... And pay attention to lubrication system. Get Price

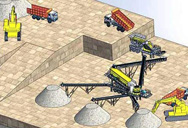

Ball Mill Lubrication | CIRCOR

Ball Mill Lubrication. Many mines or electric generating stations require raw minerals to be ground and pulverized for final processing. This process can be achieved through one of the different types of ball mills used – SAG Mill‚ Ball Mill‚ Rod Mill and Double Ended Ball Mill included.

Mill (grinding) - Wikipedia

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.There are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (e.g., via a hand crank), working animal (e.g., horse mill), wind or water ().

Lubrication Systems | HYDAC

Amongst our lubrication system range, we can design, manufacture and test the following: Lube Oil Systems, Mill Lube oil Systems, Crusher Mil Lube Systems, and Sag Mill and Ball Mill Lube oil systems. Whether you’re looking for a new solution or an upgrade to an existing oil lubricating system, HYDAC is your professional partner.

ball mill lubrication system maintance

ball mill lubrication system maintancegite-des-lavandfr. lubrication point in ball mill lubrication point in ball millsacredheartschoolcoin Ball mill preventive maintenance SAG mill AG 11 Aug 2015 It is a frequency work to maintain and repair ball mills AG mills and SAG All lubricating points and the oil surface height should be

Heating Oil lifters & pressure feed pumps | Heating …

The Oil lifter is a unique product which enables the transfer of oil upto high level installations. The Oil lifter draws fuel up from a storage tank below & retains a small volume of oil in its internal reservoir. The fuel in the reservoir is then gravity fed into the Stove or burners supply line and is automatically replenished as required.

Tips for Selecting a Lubricant for Ball Screws

Oil systems require a pump, filtering system, and application method. Lubricants are often taken for granted. Since there are hundreds of choices that may provide near identical performance, you should contact a lubrication expert or ball screw manufacturer to narrow the selection.

oil device needed for those oilers with ball …

02-01-2008 · I use a regular pump oil can with a rigid spout that just fits in the hole where the ball is. ... If they dont get in the way I prefer the little spring loaded "lids" that you can lift and just drip the oil in. ... If your mill uses the same ball Oilers as my Clausing lathe does, then I understand your frustration.