Coal Mill - an overview | ScienceDirect Topics

In coal milling for power stations, a ‘closed-loop’ process is used in which the rejects from the classifier are returned to the mill for regrinding. In VSMs, the re-circulation loop is within the mill, but some mill types would have an external loop. In fact, there are a number of re-circulation loops within a mill system. The situation is further complicated by the ‘mill reject’ streams that reject undesirable …

Coal Grinding Mill Process- KNOCK Mining machine

The coal mill is a machine that crushes coal and grinds it into pulverized coal it is an important auxiliary equipment of pulverized coal coal grinding process is a process in which the coal is broken and its surface area is add new surface areas the binding forces between solid molecules have to be overcome thus consuming is ground into pulverized coal

Use Of Coal Mill In Cement Manufacturing …

Coal Mill In Cement Production Process. Coal mill in cement production process the coal vertical mill is driven by an electric motor and driven by the planetary reducer to rotate the mill disc of the coal 24 rollers on the mill disc rotate under the drive of the mill disc the raw coal coming in through the coal falling pipe is distributed on the mill particles of coal are crushed by the relative motion of roller and the raw …

coal mill in cement manufacturing process

Production capacity: 1.9-76.0t/h. Motor power: 7.5-160kw. Application areas: mainly used for drying various bulk materials in metallurgy and stone industry, as well as drying various raw materials such as clay, coal, slag, iron powder, etc.

process coal mill - hausbau-handwerk.de

Coal mill_cement production process_Cement epc. 2019-12-10 Coal mill is one of the four auxiliary machines in thermal power station and the main equipment of pulverized coal preparation system.It is also suitable for pulverizing coal and ore in cement, metallurgy, stone industry and other industries.Special steel ball coal mill is a new type of equipment widely used in thermal power plants.

The Relationship Between Coal Mill Production …

The Relationship Between Coal Mill Production And Air Volume Feeders, coal mill, coal pipe etc.Swelling index of coal measure of increase in coal volume when heated in air, with the exclusion of air.This helps in evaluating the coal for combustion.The other important aspects of coal are.Bulk density.And.Particle size distribution.

Coal Manufacturing Process Grinding Mill

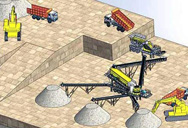

Sand and stone production line is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centrally electronic control and the designed yield is …

New "carbon-neutral" milk offsets its greenhouse …

13.07.2020 · Still, natural gas powers the pasteurisation process. “That does produce some emissions, but not as bad as coal… we have a focus on trying to switch out of coal first, but we know that on our ...

Seznamte se s moderním energetickým zdrojem | Coal Mill

Coal Mill a.s. je moderní, rozvíjející se společnost, která disponuje špičkovou technologií na zpracování černého uhlí. Byla založena v říjnu 2006 a je zapsána v obchodním rejstříku vedeném Krajským soudem v Ostravě, oddíl B, vložka 3104. Areál firmy o rozloze 17 686 m2 je situován ve výrobně– průmyslové zóně mimo obydlenou část obce Dětmarovice v ...

DSS055: Coal Mill Safety In Cement Production …

19.11.2019 · DSS055: Coal Mill Safety In Cement Production Industries With Vincent Grosskopf In this episode of the DustSafetyScience Podcast, we interview Vincent Grosskopf, founder of Coal Mill Safety . He has over 40 years of experience in bulk material handling industries, 25 of which were spent in dust explosion protection through Thorwesten Vent based in Germany.

coal mill coal mill products coal mill suppliers and

5 sets of 20tph coal ball mill for clean coal powder production line. Ball mill equipment has been put into production, bringing the economy to customer. Get Price. Pulverizer - Wikipedia. Types of coal pulverizers. Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills. A ball mill is a pulverizer that consists of a ...

Coal Mill For The Production Of Coal Slack Batu …

Coal Mill For The Production Of Coal Slack Batu Crusher We are a professional mechanical equipment manufacturer, we provide original parts, service solutions, extensive training and extensive wear, crushing chambers and screening media solutions to reduce operating costs, improve product quality and maximum productivity.

coal mill in cement production process - sozial …

coal mill in cement production process. Cement kiln - Wikipedia. Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silica-bearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process ...

Products – Coal Milling Projects

Coal mill desander. MILLING PLANT SPECIALISTS FOR POOR COAL CONDITIONS Remove sand from coal during the milling process. The Desander Patented Technology is used to extract heavy minerals out of the mill during the milling process. This has a major impact on the wear rate of the grinding elements and the down stream effects of boiler tube and ...

Newest Rod Mill For Grinding Coal Hot Production

Coal Purchace Mill In India . Coal purchace mill in indiaiihed. coal purchace mill in india. Full text of A glossary of terms used in coal mining Search the history of over 432 billion pages on the Internet. Get Prices; Hazard In A Cement Crusher Grinding Mill China . Vertical Roller Mill Production Line And Design Advantages. It plays a core ...

China Coal Mill, Coal Mill Manufacturers, …

Here we are going to show you some of the process equipments for sale that featured by our reliable suppliers and manufacturers, such as Coal Mill. We will do everything we can just to keep every buyer updated with this highly competitive industry & factory and its latest trends. Whether you are for group or individual sourcing, we will provide you with the latest technology and the ...

Coal Mill In Cement Production Process Crusher …

Coal Grinding Mill, as its name suggests, is a kind of equipment machinery for the development of coal. The function of Coal Grinding Mill is to crush and grind coal into coal powder. The grinding process of the mill is mainly crushing and hitting. Broken and ground.

Coal Grinding Mill Plant For Coal Grinding Process

As Coal Grinding Mill Plant Manufacturers, liming series crusher equipment, mill equipment and screening equipment and conveying equipment will be more support for the development of the coal industry. liming coal and other mineral rock grinding processing field has a unique technical advantages, fully meet the current mine production of large, group.