Afbeeldingen van Grinding Process Adhering

Oct 15, 2019· A grinding aid is a specialty stone agent used to make it easier to grind and mix cement Specifically, grinding aids prevent cement particles from re-agglomeration, or re-adhering, during and after the grinding process Grinding aids make it possible to streamline the cement-making process by increasing process efficiency and material fluidity

Grinding Machining Process : Complete Notes - …

23-12-2018 · The grinding process has the least material removal rate among other machining processes because of the following reasons- Size effect: As above discussed the machining is done by the abrasive action of grinding wheel that’s why a large portion of the abrasive will be embedded inside the wheel and a small portion of abrasive will be allowed to interact with them , therefore, less material …

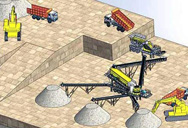

cement grinding process images - nijenoert-leek.nl

cement grinding process images 11.6 Portland Cement Manufacturing US EPA 11.6 Portland Cement Manufacturing 11.6.1 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silies, aluminates and aluminoferrites.

cement grinding process dry - Ristorante Da …

Cement kiln. Wet grinding of hard minerals is usually much more efficient than dry grinding When slurry is dried in the kiln, it forms a granular crumble that is ideal for subsequent heating in the kiln In the dry process, it is very difficult to keep the fine powder rawmix in the kiln, because the fast-flowing combustion gases tend to blow it back out again...

Grinding - LinkedIn SlideShare

Grinding 1. Grinding and Grinding Machine 2. Grinding: Grinding is a process of removing material by abrasive action of a revolving wheel on the surface of a work-piece in order to bring it to required shape and size The wheel used for performing the grinding operation is known as grinding wheel It consists of sharp crystal called abrasive held together by a binding material or bond The wheel ...

Grinding Process, Finish Machining, Aerospace …

Grinding Roughs Out a New Niche Tyrolit Advocates a Patented Grinding Process for Rough and Finish Machining of Aerospace Parts. In the past, grinding has been a process that was primarily relegated to machining for final dimension accuracy and surface finish.

TYPES OF GRINDING PROCESS - Mechanical …

Through feed grinding process is considered as quite productive as grinding process could be performed simultaneously for number of objects. In-feed grinding If we have a workpiece, which has not exactly not right circular cylindrical shape, in this situation we will prefer in-feed grinding process as grinding wheel could be dressed according to the workpiece surface.

Grinding Machine: Types, Parts, Working & …

In a grinding machine, there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley.. So when we start the electric motor the motor rotates at a certain rpm (150-15000 RPM, it may change according to the types of grinding machine) with the help of v-belt and cone pulley the grinding wheel also starts rotating and we perform the operation.

Grinding and Finishing - IIT Mechanical

Grinding – Ex. 1-1 • You are grinding a steel, which has a specific grinding energy (u) of 35 W-s/mm3. • The grinding wheel rotates at 3600 rpm, has a diameter (D) of 150 mm, thickness (b) of 25 mm, and (c) 5 grains per mm2. The motor has a power of 2 kW. • The work piece moves (v) at 1.5 m/min. The chip thickness ratio (r) is 10.

Frequent problems during grinding – grindaix GmbH

Grinding operations thus contribute greatly to the quality of the finished workpiece. However, problems can often occur during the grinding process. The biggest and most known problem is without doubt grinding burn, which is thermal damage to the rim zone of the part. Grinding burn occurs when too much heat is channelled into the part.

Principles of Modern Grinding Technology | …

Most grinding is conducted either with oil-in-water emulsions or with neat mineral oil or neat synthetic oil using a low-pressure delivery system. Grinding fluids reduce grinding temperatures in two different ways. The first is by directly cooling the process within the grinding contact area.

Grinding Barite Process - spanje-toerisme.nl

Barite Grinding Mill Plant And Flotation Machine Used In. Barite Grinding Plant in Thailand Abstract Barite is the vital material in industrial application Grinding mill plant will process the raw barite materials into powder size for further usage In mining process there …

Grinding (abrasive cutting) - Wikipedia

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.. A wide variety of machines are used for grinding: Hand-cranked knife-sharpening stones (grindstones)Handheld power tools such as angle grinders and die grinders; Various kinds of expensive industrial machine tools called grinding machines; Bench grinders

Corrosionpedia - What is Grinding? - Definition …

13-06-2018 · Grinding is a subset of cutting, as grinding is a true metal-cutting process. Grinding is very common in mineral processing plants and the cement industry. Grinding is used to finish workpieces that must show high surface quality and high accuracy of shape and dimension.

Grinding Machines Process Parts - gobeyondmba.nl

Grinding Machines Process Parts Calcite Deep Processing Plant in Belgium Calcite deep processing production line in Belgium is composed of PE250×400 jaw crusher, electro-vibrating feeder, HXM-1021 micro powder mill, hoister, electrical cabinet, packing machine and pulse dust collector.

grinding process in metals - whiskedawaybakery.nl

Grinding of metals Theory and application SpringerLink. Grinding theory is now sufficiently advanced that a logical basis exists for controlling and optimizing the grinding process In this stone a review is presented covering various aspects of grinding theory and their practical utilization A model of abrasivemetal interactions is described which accounts for the magnitude of the grinding ...

grinding is a mi ture of process

Oct 15, 2019· A grinding aid is a specialty stone agent used to make it easier to grind and mix cement Specifically, grinding aids prevent cement particles from re-agglomeration, or re-adhering, during and after the grinding process Grinding aids make it possible to streamline the cement-making process by increasing process efficiency and material fluidity

barite crusher and grinding plant in mine process

Barite mining equipment Barite mining process machines . Barite mining process Commercial barite is mined from surface or near surface deposits by open pit or underground mining methods The broken ore is trucked to the processing plant where it may be washed by log washer or trommel screen to remove adhering clay and low grade fines before reduction by jaw or impact crusher to 25 cm or finer ...

Basics of Grinding - Manufacturing

grinding machines perform the dressing task automatically. The application of coolants to the grinding process is important. Coolants reduce grinding machine power requirements, maintain work quality, stabilize part dimensions, and insure longer wheel life. Coolants are either emulsions, synthetic lubricants or special grinding oils.