4 Types of Stone Crushers Maintenace and Efficient ...

Jul 28, 2020 · 4 Types of Stone Crushers Maintenace and Efficient Improvement Jaw crusher. Jaw crusher is used for (primary crushing) coarse and medium crushing of hard stones and rocks. The working... Cone crusher. The cone crusher is suitable for (secondary crushing) medium and fine crushing …

Which stones can the jaw crusher process-Jiaozuo zhongxin ...

The shape of the product is a cube, which can be selectively crushed. It is used to crush various coarse, medium and fine stones, such as limestone, basalt, granite, concrete, slag, cement block and other materials. Jaw crusher is the equipment of crusher equipment.

Should know all about Stone Crusher Plant - Machine Thug

Types of Stone Crusher Plant Jaw Crusher. A jaw crusher is the compression kind of crusher and used for crushing rock between two heavy steel jaws. The movable jaw compresses the material against the fixed jaw and crushes material at the desired size. Material exits from the bottom of jaws. Jaw crusher adjustable …

Stone Crusher Process Flow Diagram-jaw Crusher

Stone Crushing Flow Chart Ball Mill Silica Sand 4000 Mesh. Stone crusher plant process flow chart alat pengecilan ukuran ball mill untuk pangan jual alat stone crusher sand making stone quarry grinding balls production lines stone crusher machine optimum design and analysis of swinging jaw plate of a single toggle jaw crusher …

What is the procuction process of Stone Crusher? Who can ...

Oct 15, 2013 · Answered June 17, 2020. The large stones in the plant are crushed by the coarse crusher in the jaw crusher, and they are evenly passed through the bunker by the vibrating feeder. The coarsely crushed stones are sent to the impact crusher by a belt conveyor for further crushing.

Jaw Crushers In Action! Crushing Rocks, Concrete, Granite ...

Nov 27, 2018 · Our jaw crushers have crushed a lot of different stuff over the years and we wanted to make a video of some of the best shots. We have …

Crushing technology | Technologies | Kleemann

Jaw crushers operate according to the principle of pressure crushing. The crushed material is crushed in the wedge-shaped pit between the fixed crusher jaw and the crusher jaw articulated on an eccentric shaft. The material is crushed …

Jaw Crusher|Crusher Stone Crushing And Screening Process

Crushersand Making Machinevibrating Screencrushing, For stone rock sand including crusher feeder vibrating screen and belt conveyor one set can meet all the crushing and screening process sand production line for stone sand process openpit coal mine crushing and screening plant for raw coal coal mine max i Crusher Stone Crushing And Screening Process

Jaw crushers - liming

Specifications Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce rocks to smaller sizes for the next crushing stages. Jaw crushers are a popular alternative to primary gyratory crushers, since they can process …

Crushers - an overview | ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber.

Crusher - Wikipedia

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber.

Crushers - All crusher types for your reduction needs - liming

As the name suggest, jaw crushers reduce rock and other materials between a fixed and a moving jaw. The moving jaw is mounted on a pitman that has a reciprocating motion, and the fixed jaw stays put. When the material runs between the two jaws, the jaws compress …

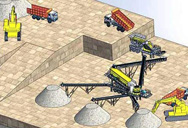

Crushing plant - Wikipedia

Process of crushing plant Raw materials are evenly and gradually conveyed into jaw stone crushing equipment for primary crushing via the hopper of vibrating feeder. The crushed stone materials are …